80 20 T Slot Framing

While having everything cut for you ahead of time is the recommended way to go, sometimes you just don’t know the length of every bar until you start building your frame. Or you just want to save some money (i.e. the cut charge).

In these cases, you are going to need to know how to cut an aluminum bar yourself. Two of the biggest advantages of aluminum over steel is its weight-to-strength ratio and the ability to cut it yourself with a standard saw.

What You Need To Know When Cutting 80/20 Aluminum T-Slot Extrusions

80/20, known as 'The Industrial Erector Set'©, is a modular T -slotted aluminum framing system offered in both inch and metric profiles. It offers extremely cost-efficient solutions to building machine frames. We’re conducting site maintenance this Sunday at 9PM Eastern. To ensure your cart is available after that time, please sign in to a customer account.

80 20 T Slot Framing Nailer

These common Questions & Answers about cutting aluminum extrusions should help you get started:

Question 1: Can I use my circular or table saw?

- 80/20 T-Slotted Framing. 80/20 T-Slotted Framing. T-Slotted Profiles. T-Slotted Profiles. Fractional T-Slotted Profiles; Metric T-Slotted Profiles; Quick Frame.

- T-Slot Aluminum Extrusion Framing – Heitek Automation. 80/20 T-slot aluminum extrusion framing enables you to design, configure and reconfigure unique custom framing and guarding solutions.

Answer: Yes, but we recommend that you use the right blade and take some measures to ensure the squareness of the cut. Aluminum t-slot bars cut at the factory use expensive, calibrated saws to maintain exact squareness.

When you use a table saw (which is preferable to the circular saw) to cut, there are a few angle errors that can occur. As table saw blades are fixed – all you need to do is make sure the blade angle is exactly 90 degrees and that the bar is square and secure before cutting. This usually involves confirming the angle of the blade, and holding the bar against the guide.

For circular saws, cutting 80/20 aluminum t-slot extrusions is a little more tricky. First make sure the base plate is parallel to your blade if you are going to use it to line up the cut. Like a table saw, also make sure the angle is set exactly to 90 degrees. Now, the tricky part is getting the blade through the aluminum without tilting the saw left or right. It might be worthwhile to set up some type of jig to ensure your Saw cannot rock back and forth as you move down, so the cut is square.

Question 2: What is the best blade to use for cutting 80/20 aluminum t-slot extrusions?

Answer: The best type of blade is a high-speed .375” steel blade with 60 – 72 teeth and carbide tips. Make sure the blade is a double or preferably a triple chip – this basically alternates a flat “rager” tooth with a higher “trapeze” tooth that divides the chips when cutting harder materials like Aluminum – also called non-ferrous. Cutting 80/20 aluminum t-slot extrusions is relatively easy as they are composed of aluminum alloy 6105-T5 – which is specifically formulated for machining.

Question 3: Should I lubricate the blade while cutting?

Answer: Yes, you should definitely lubricant the blade with vegetable oil or a commercial lubricant like WD-40 or Trim Sol. If you don’t use lubricant, the blade will heat up quickly and the chips will re-weld themselves to the teeth of your blade. Avoid this!

Question 4: What RPM should I use?

Answer: If you can change the RPM of your saw, then you should use a slower speed. The saw’s RPM has to be matched with how fast you are pushing the blade through the aluminum and how thick the bar is. The faster you want to cut, the faster the RPM needs to be. If you move the blade too fast through the material, the blade will heat up and generate a lower quality cut. In general, you will have to go slower than what you are used to for wood.

Question 5: Any other recommendations?

Answer: Yes – definitely. Cutting 80/20 aluminum t-slot extrusions can be dangerous, so here are 5 safety precautions you should take:

- Use eye protection as cutting 80/20 aluminum t-slot extrusions generates a fair amount of hot flying metal chips. A face shield is better.

- Cutting aluminum can be loud so hearing protection is also highly recommended.

- Respiratory protection is recommended as dust created by aluminum cutting is toxic. Lubrication reduces this substantially and not everyone uses respiratory protection, but we recommend it.

- Make sure your bar is well secured. We highly recommend clamping it down securely before cutting. But if you don’t make sure it is held very securely. A loose bar of aluminum is one of the most dangerous things in the shop.

- Plan on deburring the end of the bar with a polishing wheel, metal file or metal sand paper. Even with a quality cut, the edges will be sharp and there may be small chips that will easily cut a hand or finger.

80 20 T Slot Aluminum

Summary

Cutting 80/20 aluminum t-slot extrusions is fairly simple with common saws if you follow the recommendations above. Why use or cut aluminum extrusions? Click here for 5 great reasons.

Having us cut your extrusions is far safer and likely more accurate. But just in case, we hope you have enjoyed this article. Want to make sure you get future articles – register now. Have questions? Give us a call at 1-858-602-1500 – we will be happy to help you.

80/20, known as 'The Industrial Erector Set'©, is a modular T -slotted aluminum framing system offered in both inch and metric profiles. It offers extremely cost-efficient solutions to building machine frames, guards, work stations, retrofit projects and more... basically anything ... and we do it all right here at Fiero Fluid Power! We maintain extensive product inventories and provide in-house services including in-depth CAD support and building complete value-added assemblies.

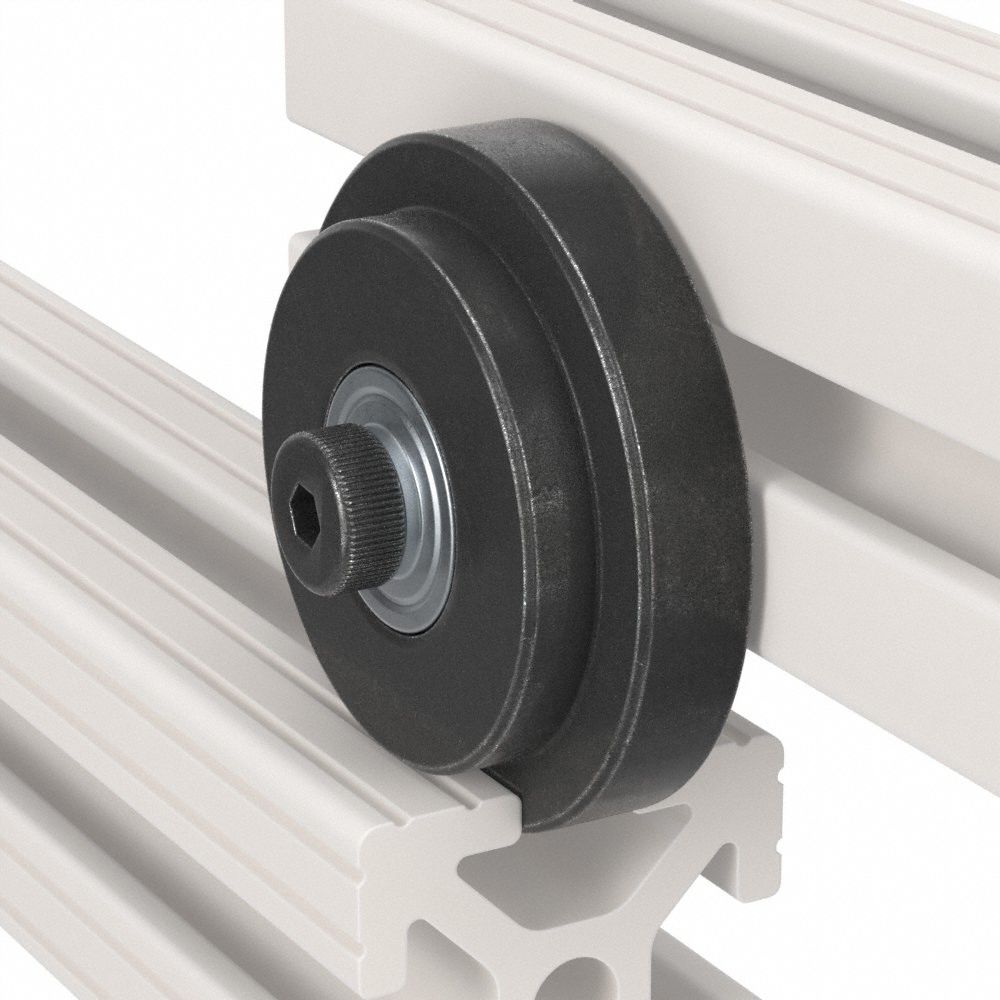

80/20’s modularity is based upon the T-slot concept of our profiles. The 'T' shaped slots present on all of our profiles allow for infinite positioning along the axis. While there are other types of T-slotted profiles in the industry, one modification to the 80/20 line is a slight adjustment to the ' T' which creates the 2° Drop-Lock Feature. When a fastener is tightened to (or beyond) the necessary torque, the flange will flex up to the adjoining profile, thus creating pressure which prevents the fasteners from vibrating loose.

Some of the Benefits of 80/20 Framing Products:

- No welding - no fighting heat stress or warping

- No painting

- Light weight

- Easy to machine

- Much less engineering time is required

- Only simple hand tools are needed for assembly

- No expensive fabricating equipment is required

- Machine frames can be easily re-configured for design changes

- Great aesthetic appearance

80/20 Home Page